Design

Have you ever been involved by the design’s developing?

SAMEC does!

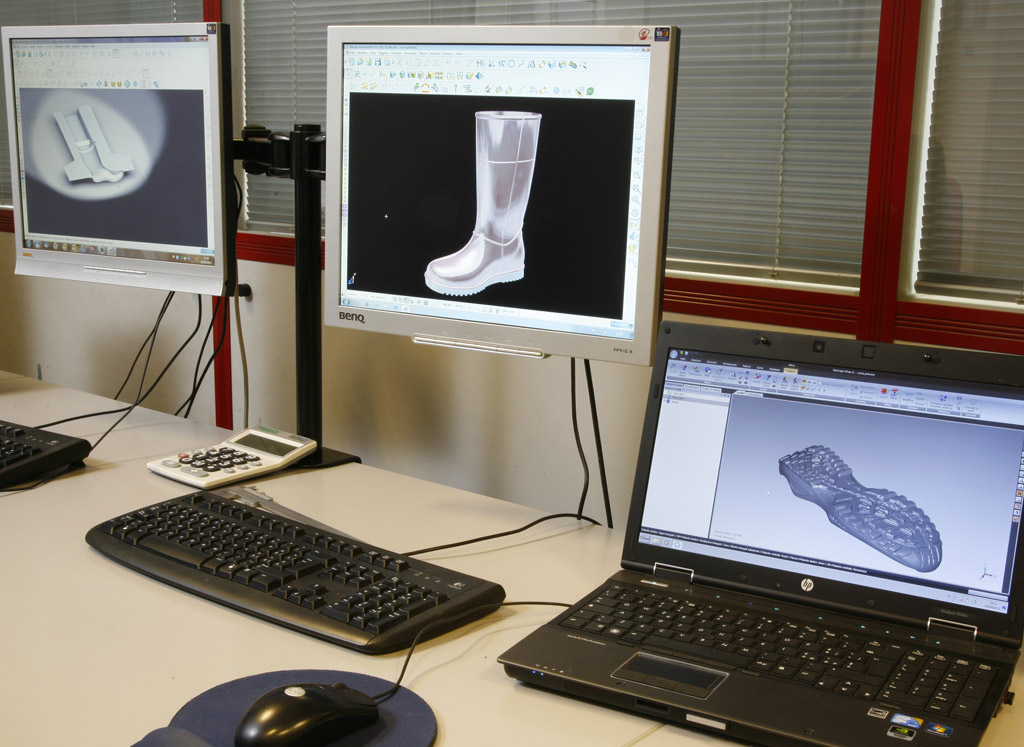

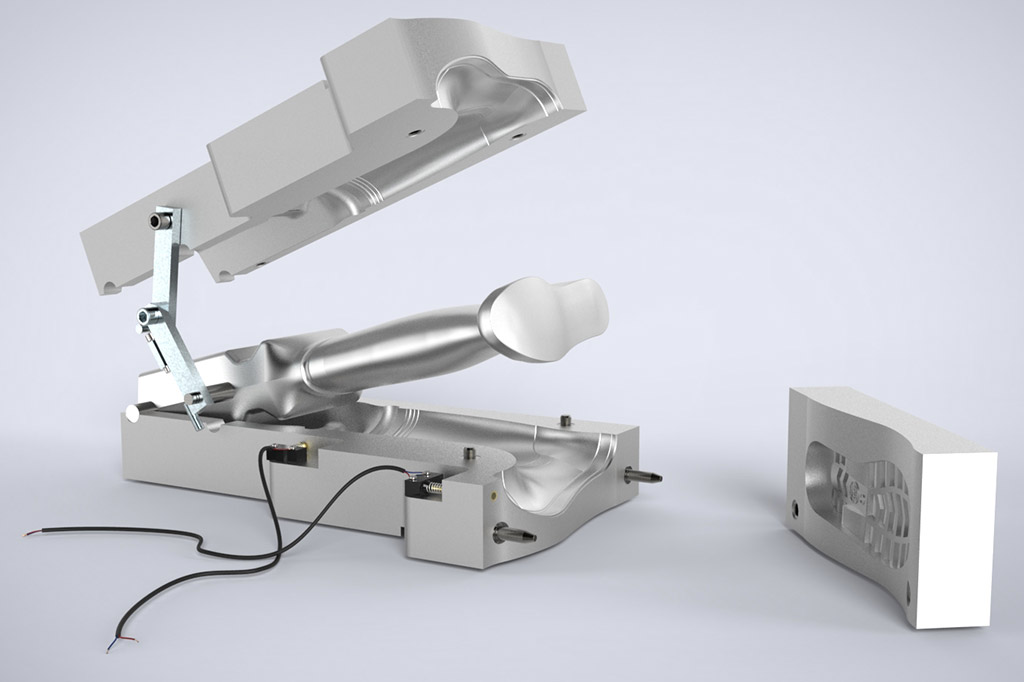

Our R&D deparment creates for its customers a preview of the product. Through advanced CAD/CAM 3D rendering programs, the customer can change the characteristics of the product before the production starts, that results in time and quality advantages. The product’s time-to-market gets shortened. The rendering can be preceded by a three-dimensional scan of the models provided by the customer. To achieve optimal results, each department operates in close contact with the next unit.

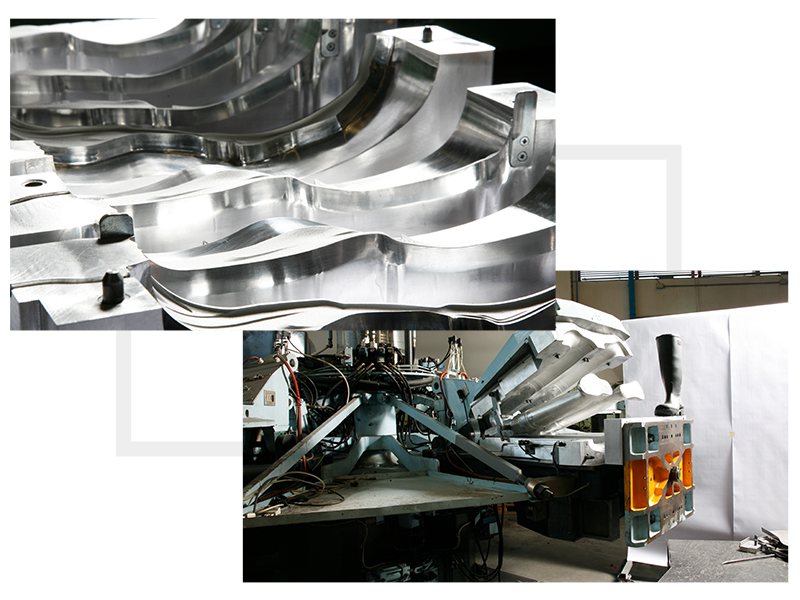

The CNC machines (5 and 6 axes) are operating 24 hours and 7 days a week if needed. Thanks to our computer systems we can guarantee high production and high quality.

For an awesome result,

the department work together

with any productive units.

The computer numerical control machines can reproduce an high amount of pieces,

with that accuracy that only our system can ensure.

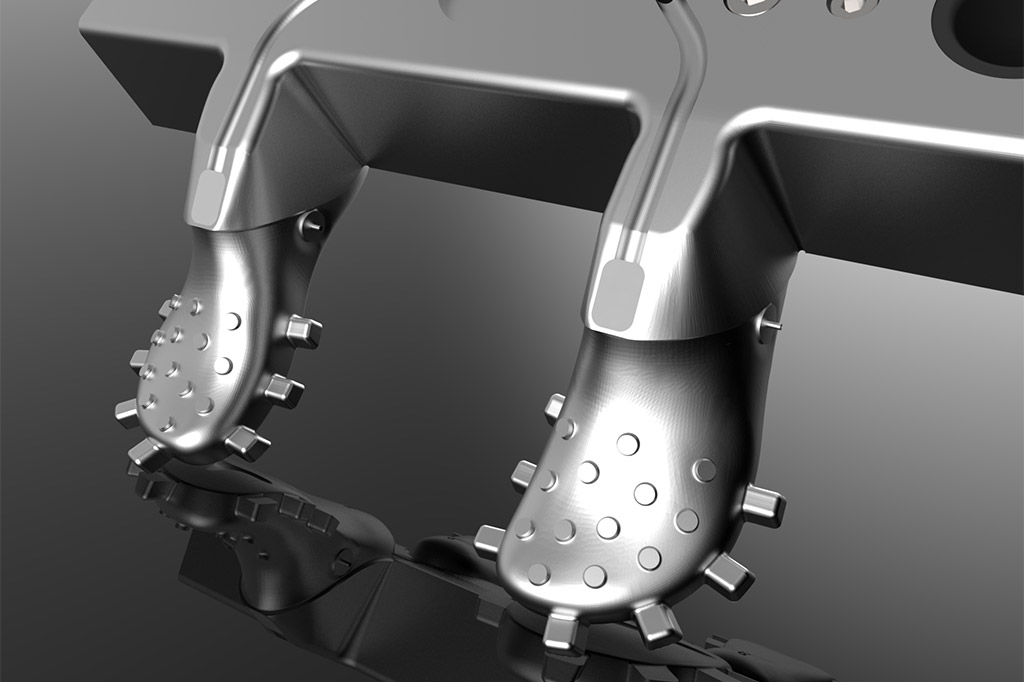

Control and testing

We apply to all work steps careful ckecks. The first control take place in the technical dept. and continue till the project is fulfilled. The final test guarantees the full funcionality of the moulds.

Samec manufactures moulds for following machines’brands: Main Group, Desma, Wintech, Ottogalli, Industrial Service and more.

We test moulds by using following materials: PU-PU, TPU-PU, RUBBER-PU, PVC, EVA, PEBAX – Nylon.

Materials

High Quality Moulds made with european raw materials.

Trained Stuff, innovative technical solutions, advanced production systems are the key of our success.

We manufacture Moulds for all common materials:

TPU, PU, PVC, TR, SEBS, Rubber, EVA.

We are specialized in the processing of thermoplastic materials and rubber.